- Home

- Products

- Enameled Wire

- Enameled Copper Wire

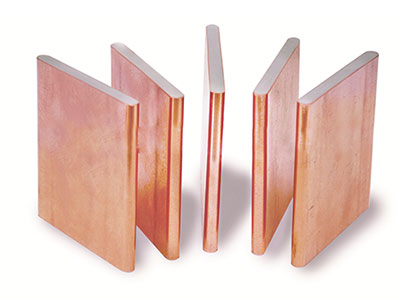

Enameled Copper Wire, Flat Wire

The enameled copper wire (magnet wire) has a copper conductor covered with an insulation layer, it is produced by softening of bare copper wire through the annealing process and then apply insulating paint evenly on the surface of copper wire for multiple times before being baked to solidify the insulating paint layer. Our enameled copper wires are widely used in a variety of coil winding applications including electric motors, transformers, solenoids, wound coils, etc.

Enameled copper wire diameter: 0.05mm--6.00mm

Both round and flat enameled copper wires are available.

- Corona resistant enameled copper wire

- Polyester enameled copper wire

- Modified polyester enameled copper wire

- Polyester imide enameled copper wire

- Polyurethane self solderable enameled copper wire

- Composite polyester imide/polyamide imide enameled copper wire

This magnet wires are vital to a wide range of products including electric motors, transformers, solenoids, wound coils, etc. in industries of refrigerator and freezer, air conditioner compressor, and other industrial and home appliances.

Spool size: PT4, PT10, PT15, PT25;

Founded in 2006 as a metal wire manufacturer, Huawang specializes in engineering and manufacturing a broad range of bimetallic compounds that can be used as various types of composite conductors in electrical and electronics industry. Our extensive portfolio of specialty wires includes magnet wire, bare wire, stranded wire, busbar, etc. We have deep passion and aim to be associated with customers who are looking for cable conductors, coil wires, winding wires, or lead wire for their electronic components.

Huawang offers a broad range of high quality wires and raw materials including bare wire, busbar, stranded wire, tinned wire, silver plated wire, enameled wire, copper clad aluminum, copper clad steed, etc. We have a large inventory of wires of various specifications for quick delivery. Besides, we can also respond quickly with products tailored to your specific needs.

-

Products

- Copper Clad Aluminum Wire (CCA/CCAM Wire)

- Copper Clad Steel Wire (CCS Wire)

- Copper Clad Copper Wire (CCC Wire)

- Composite Round (Tinned) Copper Wire

- Tinned Wire

- Silver Plated Wire

- Nickel Wire

- Enameled Wire

- Stranded Wire

- Copper Clad Aluminum Busbar (CCA Busbar)

- Aluminum Alloy Wire and Rod

- Nickel-chromium Alloy Wire

- Industries