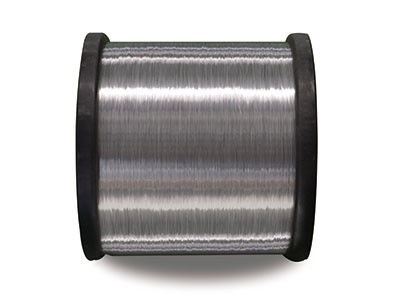

Copper Clad Steel Wire (CCS Wire)

Copper clad steel wire or CCS wire combines a steel rod or steel wire as its core with a concentrically clad copper coating. The metallic cohesion provides this conductive wire with high tensile strength of steel and conductivity properties of copper. As the copper permanently bonded on the surface of the steel core, it efficiently prevents the steel from corrosion and allows a single of this bi-metal wire to be processed with drawing and annealing treatment. This CCS wire can maintain the ratio of copper and steel unchanged during the drawing process, while the copper volume ratio remains relatively constant. Since the signal itself travels on the outer edge of the center conductor which is called “skin effect”, this makes copper clad steel wire and copper clad aluminum wire possible to transmit high frequency signal (over 5MHz) with the same conductivity of the pure copper wire.

CCS wire diameter: 0.08mm-25.00mm

- Conductor of coaxial cable for television signal distribution

- Conductor of LAN cable and Internet access cable

- Connector pins of electronic components

- Overhead conductor for power transmission and telephone line

- Overhead catenary wire, overhead conductor of overhead contact system

- Cable metallic sheathing

- Grounding conductor / earth rod

- Conductor material for medical equipment cable

- Connector for heat resistant wires and cables

- Center core of high temperature RF cable

- Conductor of high frequency signal transmission cable

Spool size: DIN 100, DIN 130, DIN 180, DIN 250, DIN 400, DIN 500, DIN 630, DIN 800;

Founded in 2006 as a metal wire manufacturer, Huawang specializes in engineering and manufacturing a broad range of bimetallic compounds that can be used as various types of composite conductors in electrical and electronics industry. Our extensive portfolio of specialty wires includes magnet wire, bare wire, stranded wire, busbar, etc. We have deep passion and aim to be associated with customers who are looking for cable conductors, coil wires, winding wires, or lead wire for their electronic components.

Huawang offers a broad range of high quality wires and raw materials including bare wire, busbar, stranded wire, tinned wire, silver plated wire, enameled wire, copper clad aluminum, copper clad steed, etc. We have a large inventory of wires of various specifications for quick delivery. Besides, we can also respond quickly with products tailored to your specific needs.

-

Products

- Copper Clad Aluminum Wire (CCA/CCAM Wire)

- Copper Clad Steel Wire (CCS Wire)

- Copper Clad Copper Wire (CCC Wire)

- Composite Round (Tinned) Copper Wire

- Tinned Wire

- Silver Plated Wire

- Nickel Wire

- Enameled Wire

- Stranded Wire

- Copper Clad Aluminum Busbar (CCA Busbar)

- Aluminum Alloy Wire and Rod

- Nickel-chromium Alloy Wire

- Industries